Project quality is a unique aspect of project management, in that it lurks in behind the scenes. Time and money (budget) are usually the biggest factors in project success, but inadequate focus on quality can sneak up and trip up a project at least as much as those two factors.

On top of that, the minimum quality standards are often difficult to define and subject to stakeholder whims.

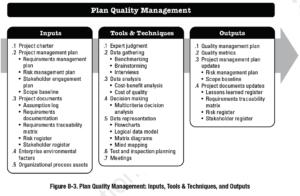

For these reasons, the Project Management Institute (PMI) identifies project quality planning as the first of three steps to effective project quality management. It is the first of three processes within the Project Quality Management knowledge area.

The Project Quality Management Plan

The main output of this process is the Quality Management Plan, which is a component of the overall project management plan. This plan identifies what the project quality standards are, how they will be met, and how they will be measured.

The three primary components of a quality management plan are:

- Quality Standards. Most industries have quality standards that can be taken ‘off the shelf’ and used for the project. Organizations such as ASTM, IEEE, or ANSI exist solely to develop standards for you, their customer, to use as a measuring stick for your project quality. These types of organizations can provide a tremendous competitive advantage when utilized effectively.

- Quality Measurement. How will adherence to those standards be measured? Sometimes it’s obvious, but other times significant room for debate exists, like when a newly paved road has a few small cracks in it. These measurement techniques should be outlined in the project management plan, up front.

- Inspection. When the project quality will be inspected, what things will be recorded, and what types of data will be communicated are important variables to consider in the project management plan.

Quality Control vs. Quality Assurance

The Quality Management Plan identifies the methods used to ensure the quality of the products meet the quality specifications. It does this in two ways:

- Quality Control measures a portion of the outputs to determine conformance to specifications.

- Quality Assurance measures the processes used to attain the quality standards.

Cost-Benefit Analysis

Quality impacts the bottom line. Each project deliverable provides a benefit to the customer and comes with an associated cost. Analyzing both sides of this equation can lead to reduction or even elimination of unnecessary deliverables.

Cost of Quality

When an earlier project deliverable is produced with low quality, future deliverables will almost always continue with the quality issues.

PMI says that cost of quality includes all costs incurred over the life of the project or product by investment in preventing non-conformance to requirements, appraising the product or service for conformance to requirements, and failing to meet requirements (rework).

Cost of Conformance

- Training

- Document processes

- Equipment

- Time to do it right

- Testing

- Destructive testing loss

- Inspections

Cost of Non-conformance

- Rework

- Scrap

- Liabilities

- Warranty work

- Lost business

Control Charts

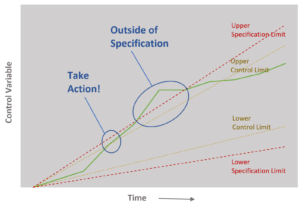

Control charts define the point at which action needs to be taken to ensure a variable remains within specifications.

Control charts define the point at which action needs to be taken to ensure a variable remains within specifications.

- The Upper Specification Limit (USL) defines the upper tolerance of acceptable results.

- The Lower Specification Limit (LSL) defines the lower tolerance of acceptable results.

- The Upper Control Limit (UCL) defines the point at which the results are flagged for specific action.

- The Lower Control Limit (LCL) defines the point at which the results are flagged for specific action.

For example, you could monitor project hours with a control chart that has time on the x-axis and hours spent on the y-axis. At the project outset five lines are drawn. The first is the planned hours worked, the second and third are the upper and lower control limits, and the fourth and fifth are the specification limits. The control limits are the point at which action must be taken to correct the variance, and the specification limits are the point at which the project is outside the specifications of the project.

Benchmarking

Benchmarking involves the comparison of actual or planned project practice with those of comparable projects to identify best practices, generate ideas for improvement, and provide a basis for measuring performance.

Design of Experiments

This is a statistical method which identifies factors which may influence specific variables of a product or process under development or in production. For example, automotive designers could use this technique to determine which combination of tires and suspension will product the most desirable ride characteristics.

Statistical Sampling

Statistical sampling involves choosing a part of a project deliverable set for inspection, for example, choosing 10 engineering drawings out of 75 for an inspection for certain quality criteria.

Flowcharting

A flowchart of the project schedule can be a great way to show the relationships between various project steps and can be an invaluable tool to find project quality issues. They can help the project team anticipate quality problems.

Proprietary Quality Management Methodologies

Many proprietary methods for managing project quality exist, including Six Sigma, Quality Function Deployment, CMMI, Total Quality Management, Balanced Scorecard, etc.

Brainstorming

Sometimes, getting the project together and brainstorming for potential quality problems is the best way to ensure a high quality outcome.

Affinity Diagrams

These are a great tool to visually identify logical groupings based on natural relationships. They can draw out the potential quality issues in a snap.

Force Field Analysis

Diagrams of the forces for and against change. Before any project changes occur, this is an interesting way to make sure that quality remains high throughout.