| Symbol |

Description |

Notes |

|

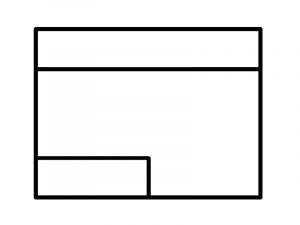

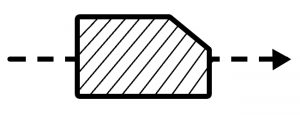

Process |

A manufacturing process. For example, cutting, stamping, or painting.

The small box represents an information system being used by the process. |

|

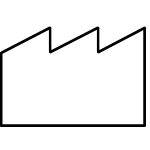

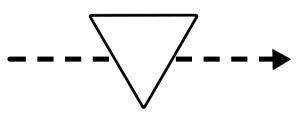

External Supplier |

An external source of raw material, services, or supplies.

The name of the organization should be labelled within the symbol, for example, “XYZ Manufacturing.” |

|

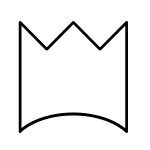

Customer |

The destination of the plant’s output.

The name of the organization should be labelled within the symbol, for example, “Bob’s Distribution.” |

|

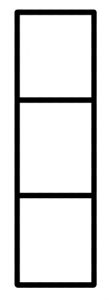

Data Box |

Information about a process, department or facility. |

|

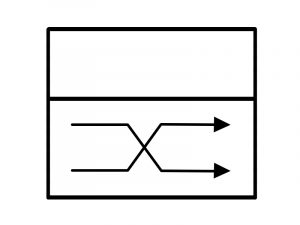

Cross-dock |

A facility where incoming materials are transferred immediately to outbound shipping, without processing. |

|

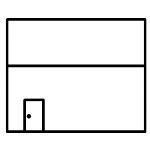

Warehouse |

A facility where inventories are placed in storage for an extended period of time. |

|

Movement of Inventory |

An open arrow signifies the movement of product from one process to the next. |

|

Push movement |

A “push” movement of materials is initiated within the plant, rather than by the customer. |

|

Truck shipment |

A shipment via road.

The frequency of shipments should be labelled below the symbol, for example, “daily.” |

|

Train shipment |

A shipment via rail.

The frequency of shipments should be labelled below the symbol, for example, “M, W, F.” |

|

Boat shipment |

A shipment via boat.

The frequency of shipments should be labelled below the symbol, for example, “monthly.” |

|

Air freight |

A shipment via air.

The frequency of shipments should be labelled below the symbol, for example, “weekly.” |

|

Information flow |

A simple arrow indicates information flow between processes. For example, the production control center communicates with each process. |

|

Electronic information flow |

A broken arrow indicates electronic information flow between processes.

For example, the production control center receives orders from the customer. |

|

Inventory |

A location of inventory storage. Usually this occurs between processes as well as the start and end of the manufacturing process. |

|

Inbox (paper queue) |

The inbox is used to indicate where an order backlog exists. |

|

Electronic inbox |

The electronic inbox is used to indicate where an electronic order backlog exists. |

|

Delay time |

Used to indicate where a delay is planned into the process, due to unavailable resources, manpower, etc. |

|

Supermarket |

A controlled inventory of work that is used to schedule upstream production. The open side faces the supplying process. |

|

Withdrawal |

Used to indicate where a downstream process is pulling from an upstream supermarket. |

|

First-in-first-out station |

Used to indicate a “first in, first out” flow of material between processes. |

|

Service level agreement flow |

Used to indicate a delivery of materials governed by a Service Level Agreement (SLA). SLA’s usually have governing criteria like minimum quantities or maximum delivery time. |

|

Schedule information |

Indicates an information flow or schedule. |

|

Production kanban |

A kanban card. The card initiates a process to produce a product, and stays with the product from raw material to finished good. |

|

Withdrawal kanban |

A kanban card used for transferring parts from a consuming process. |

|

Signal kanban |

Signal kanban indicates when a batch of raw materials has been depleted and a new batch is required. |

|

Kanban arriving in batches |

Multiple kanban cards moving through the assembly process together. |

|

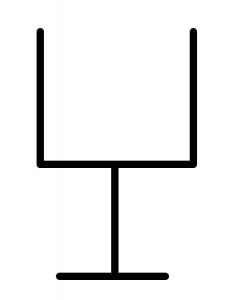

Kanban post |

A place where kanban cards are collected and held for conveyance. |

|

Buffer / Safety stock |

A buffer, or an inventory of raw materials intended to compensate for variation within the production times of a process. |

|

Load leveling |

A tool to intercept batches of kanban cards and level their volume and mix over time, to smoothen the production process. |

|

Iteration or network |

A symbol placed within a process to show that it requires repetition. Planned repetition is called iteration, whereas unplanned repetition is called rework. |

|

Kaizen burst |

Used to indicate where kaizen (continuous improvement) activities will be focused.

The specific type of kaizen activity and any supporting information is noted within the bubble. |

|

Worker / Operator |

Indicates where an operator or worker is required. Operators are not normally shown on the value stream map, but where one needs to be identified for clarity, this symbol is used. |

|

Milk run |

Indicates a worker movement to pick up parts, equipment, or supplies. |

|

Phone |

Used to indicate expedited information |

|

Expedited movement |

Used to indicate expedited movement of materials. |

|

Milestone pacing |

Indicates milestones that correspond to specific dates. |

|

Go-see scheduling |

The process requires a schedule adjustment or confirmation by an operator. |